Manual lubrication in industrial environments can be time-consuming, inconsistent, and often overlooked — leading to costly breakdowns, excessive wear, and unnecessary downtime. As businesses seek smarter and more efficient maintenance solutions, automatic lubrication systems (ALS) have emerged as a powerful way to cut costs and boost performance.

In this post, we’ll explore the ROI of automatic lubrication systems, how they compare to manual processes, and how to calculate the financial gains of automation. With over 250 years of combined team expertise, Pure Lubrication specialises in delivering tailored ALS solutions that increase productivity and protect your equipment investment.

What is an Automatic Lubrication System (ALS)?

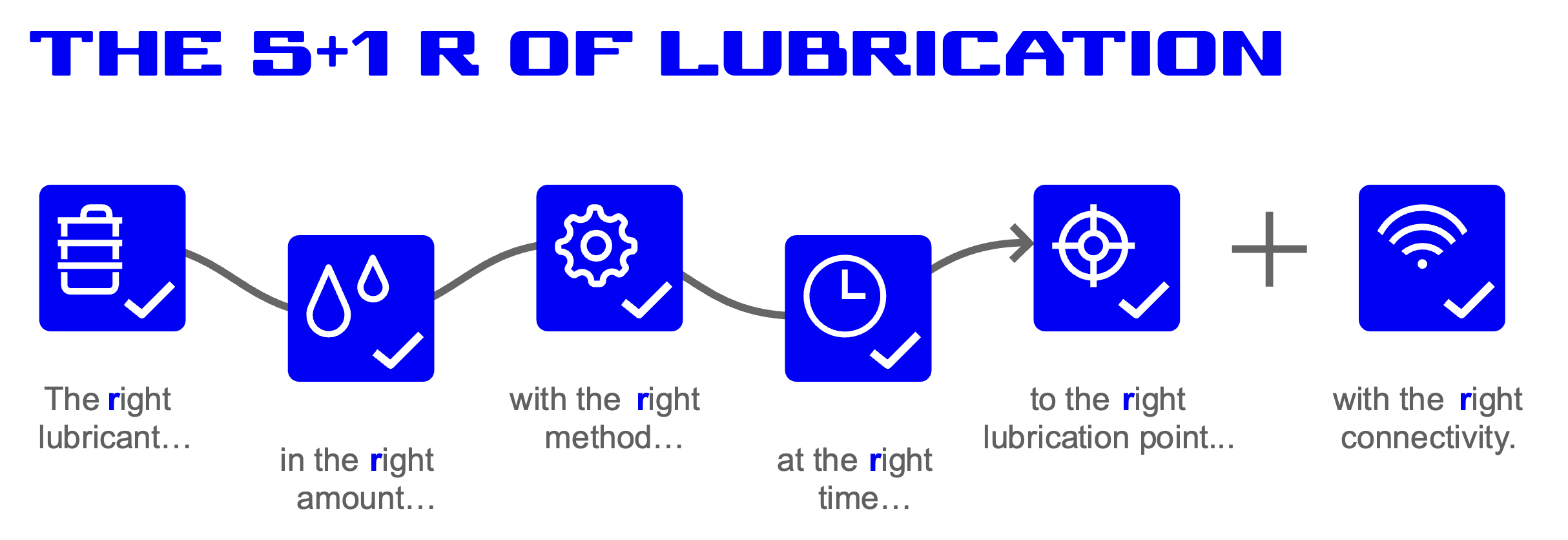

An automatic lubrication system (ALS) is a precision-based system that delivers the right amount of lubricant to machinery components at optimal intervals — all without human intervention. This ensures consistency, reduces waste, and helps eliminate human error.

ALS typically includes:

- A centralised pump unit

- Distribution metering valves

- Lubricant reservoir

- Distribution pipework

- Controller (not always required)

At Pure Lubrication, we offer a wide range of ALS types, including single-line, dual-line, multi-outlet and progressive systems, with SKF’s world-leading technology at the core. These systems are engineered to serve everything from small industrial machines to large process lines.

The Hidden Costs of Manual Lubrication

Manual lubrication might seem simple, but the hidden operational costs can be significant. Let’s break it down:

Calculating Downtime Costs

Unscheduled downtime during manual lubrication is expensive. Here’s a simple formula to estimate the cost:

Downtime Cost = (Hourly Production Loss + Operator’s Hourly Cost Rate) x Hours of Downtime per Year

For example:

If production loss is £1,000/hour and the operator rate is £50/hour, and downtime totals 40 hours per year:

(£1,000 + £50) x 40 = £42,000/year

What are the Labour Costs and Other Direct Costs?

- Time

Manual lubrication tasks often require skilled staff and take hours to complete. - Waste

Over-application of grease and spills are common, increasing lubricant consumption. - Breakdowns

Inconsistent lubrication can lead to premature wear, part replacements, and higher repair bills.

The Financial Benefits of an Automatic Lubrication System

Installing an ALS brings measurable savings across several fronts:

- Controlled lubricant usage often leading a reduction in consumption

- Cut spare parts and maintenance costs by preventing lubrication-related failures

- Lower labour costs by automating repetitive tasks

Increased Productivity and Equipment Lifespan

Consistent lubrication:

- Minimises unplanned downtime

- Improves machine efficiency

- Extends the lifespan of bearings, gears, and other key components

The result? Better output, fewer breakdowns, and long-term cost reduction.

How to Calculate the ROI of an ALS: A Step-by-Step Guide

Wondering if an ALS is worth the investment? Here’s how to calculate it:

Step 1: Determine the Cost of Your ALS

ALS pricing varies depending on system type, equipment, and installation complexity. Contact Pure Lubrication for a tailored quote — we provide SKF systems backed by expert support.

Step 2: Calculate Your Annual Manual Lubrication Costs

Ascertain the total of:

- Labour hours and full employment costs

- Lubricant consumption

- Downtime costs

- Repair/replacement costs

This gives you your baseline manual lubrication expense.

Step 3: Calculate the ROI

Use this simple formula:

ROI (%) = (Annual Manual Lubrication Costs – Cost of ALS) x 100%

Cost of ALS

If your ‘manual’ costs are £20,000/year and the ALS costs £10,000:

ROI (£20,000 – £10,000) x 100% = 100%

£10,000

The result – the system pays for itself in one year and then begins delivering a net benefit.

Why Choose Pure Lubrication for Your Automatic Lubrication System?

At Pure Lubrication, we combine:

- Decades of industry expertise

- Tailored system design

- Nationwide support

- A trusted partnership with SKF, the global leader in lubrication technology

Whether you’re upgrading a single machine or planning a full site-wide installation, we provide the insight, equipment, and service to deliver maximum ROI — fast.

Ready to calculate your ROI?

📞 Contact our experts today for a free site survey and a no-obligation quote on a bespoke SKF Automatic Lubrication System. We support you in preparing the ROI and submission of CAPEX request.