Lubrication Engineers Inc. and Pure Lubrication

Pure Lubrication is the authorised UK distributor for Lubrication Engineers Inc, supplying LE products and services.

Lubrication Engineers are an innovative company that share the Pure vision and values and key to everything they do is providing solutions for customers, ensuring their equipment and business runs smoothly.

Partnering with Lubrication Engineers allows us to offer leading edge products that enhance reliability, reduce maintenance and increase efficiency and productivity, no matter what the industry.

Lubrication Engineers Ranges & Products

Offering a fantastic range of enhanced performance lubricants, greases and equipment, Lubrication Engineers products provide reliable, cost effective solutions for a wide range of business sectors, including:

- Pyroshield® Syn Hvy & Syn XHvy Open Gear Lubricants

- Almagard® Vari-Purpose Lubricant

- Duolec® Industrial Gear Oil

- Monolec® Turbine Oil

- Endure™ Turbine Oil

- Almagard® Vari-Purpose Lubricant

- Pyroshield® Syn Hvy & Syn XHvy Open Gear Lubricants

- Multilec® Industrial Oil

World Class Service at a Local Level

Our team of friendly experts with over 200 years of lubrication experience are here to help you. We would love to talk to you about Lubrication Engineers and how careful selection of the right product for the right application can deliver solutions that help you achieve maximum productivity.

Click here to download the brochure for Lubricants for Food & Beverage Industries

Click here to download the brochure for Lubricants for the Water & Wastewater Treatment Industries

Click here to download the brochure for Xport Single Point Lubricators

Asset Reliability Solutions

Single Point Lubricators

Add reliability to your lubrication program with dependable, automatic re-greasing

Incorrect or inadequate lubrication results in equipment damage that can lead to breakdown. In many cases, single point lubricators are the solution to this problem. With Xport® Single Point Lubricators filled with LE lubricants, you can deliver the right lubricant, in the right amount, to the right place, at the right time – 24/7.

- Ensure critical applications receive lubricant 24/7

- Eliminate application of the wrong lubricant, avoiding costly cross-contamination issues

- Eliminate under- or over-application of lubricant

- Increase safety with installation in hard-to-access locations

- Keep dust and moisture out of the equipment with hermetically sealed lubrication points

Xport® Single Point Lubricators are rugged, durable and easy to install. They are perfect for mining operations, steel manufacturers, power plants, water and wastewater treatment facilities, cement plants, food processing plants, and manufacturing facilities of all types. Xport SPLs are installed on millions of roller and slide bearings, blowers and fans, chains, pumps, presses, motors, open gears, and conveyors across the globe.

The Xport® Ultra is a fully automatic lubrication system, independent of temperature and counter pressure with a very precise discharge. With two cartridge sizes, pressure build-up to 725 psi / 50 bar, options of weekly and monthly time settings, the Xport Ultra is an extremely versatile and capable lubrication system suited to a wide range of applications which demand high lubrication rates and where long remote grease lines are necessary to ensure safe access.

Typical Applications: Drag conveyors, shaker screens, rotary kilns and belt conveyors

Typical Industries: Environmental technology, food industry, oil and gas production, paper industry, pharmaceutical industry.

The Xport® Star Vario automatic single point lubricator operates fully automatically, independent of temperature, and offers a very precise discharge. It is ideal for applications that require precise lubricant metering, and is a preferred system for electric motors with very specific re-lubrication amounts.

Typical Applications: Chains, electric motors, gear racks, open gears, roller and sliding bearings, shaft seals, sliding guides, spindles

Typical Industries: Environmental technology, food industry, oil and gas production, paper industry, pharmaceutical industry

Xport® Star Control Lubricator

The Xport® Star Control automatic single point lubricator is ideal for applications that require precise lubricant metering, and it is a preferred system for electric motors with very specific re-lubrication amounts. The Star Control is supplied with external power via cable, and its operating status can be transmitted to a PLC via this connection. This system offers two operating modes – time and impulse – for more flexibility. In time mode, lubricant dispensing is dependent on operating hours.

Typical Applications: Chains, electric motors, gear racks, open gears, roller and sliding bearings, shaft seals, sliding guides, spindles

Typical Industries: Mining, recycling industry, power plants, food industry, paper industry

Xclude® Desiccant Breathers

Lubricant contamination is one of the leading causes for machine failure, and contamination can begin before the lubricant ever enters the machine. Gearboxes, pumps and reservoirs have to “breathe” when the air expands and contracts, as well as when incoming fluid displaces air, or when air is drawn in when hydraulic components activate.

Each time a unit breathes in, it brings with it all sorts of small debris and moisture, depending on the operating environment. Over time, the effects of this contamination can be damaging to the lubricant and to the equipment.

Xclude Desiccant Breathers:

- Eliminate rust-forming condensation

- Prevents sludge deposits and water contamination

- Reduces wear and tear on equipment

- Provides longer oil and filter life

Providing basic protection from moisture and particulate contamination in lubricants and equipment, Xclude® Standard Breathers replace the standard dust cap or OEM breather cap on equipment. They work great in totes, transformers, storage tanks and hydraulics in a variety of industries. They are convenient and simple to install. Their clear casing allows easy viewing of color-indicating desiccant in order to monitor when the breather should be replaced. They can withstand high vibration and volatile environments.

Xclude Extended Series Breathers

Xclude® Extended Series Breathers are high-airflow, long-lasting desiccant breathers with check-valve technology. They are ideal for storage tanks, large gearboxes, wind turbines and remote applications. When air is expelled from the container, the top foam pad prevents oil mist from contacting silica gel or entering the atmosphere. The breather is outfitted with a resilient nylon standpipe and polypropylene oil mist reducer to allow oil mist to coalesce and drain back into the reservoir, rather than compromising the desiccant.

Xclude High Humidity Expansion Chamber Breathers

Xclude® High Humidity Expansion Chamber Breathers are best suited for low-flow gearboxes and high-humidity applications with continuous operation. These high humidity desiccant breathers feature an expansion chamber to isolate lubricants from all levels of ambient humidity, keeping out harmful particles and creating a nearly sealed system to protect the equipment.

Xclude® Extreme Duty Breathers are designed to take the abuse of vibration and impact, broad temperature range, chemicals and other challenging environments, making them an ideal solution for application such as mobile and off-road equipment, hydraulics and nautical applications. Quality check valves isolate the system while accommodating airflow. The visual indicator windows show the desiccant as it changes color, indicating that the breather should be replaced

Xclude Rebuildable Steel Breathers

Xclude® Rebuildable Steel Breathers for high-flow applications feature a rugged housing to protect equipment from moisture and contaminants, even in the toughest environments. Rebuildable steel breathers are perfect for hydraulic reservoirs, bulk oil storage, diesel tank storage, and where chemical or harsh environments exist. Rebuildable Steel Breathers can be ordered in a variety of different materials to meet chemical compatibility needs

Xclude Non-Desiccant (ND-2) Breather

Xclude® Non-Desiccant (ND-2) Breathers prevent contamination when humidity is not an issue. They can be used for applications such as oil sight glasses and small gearboxes. As wet, contaminated air is drawn through the unit, the hydrophobic media repels water while the particulate filter captures dirt, preventing both from entering the equipment.

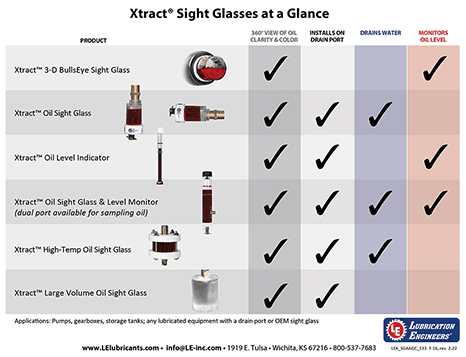

Oil Sight Glasses

The Xtract sight glass product line enables continuous visual monitoring of the clarity, color, sediment and water contamination levels of your lubricants. Some models even allow you to easily remove the water by draining it right out of the system. The variety of sight glass solutions available will help advance your lubrication reliability program to the next level.

- Xtract® Oil Sight Glass

- Xtract® High Temperature Oil Sight Glass

- Xtract® Large Volume Oil Sight Glass

- Xtract® 3D BullsEye Sight Glass

Who are the Lubrication Engineers Inc.?

A leader in lubricants since 1951, Lubrication Engineers, Inc. make reliability easy for customers, creating solutions for even the toughest lubrication challenges in a variety of industries worldwide.

LE boosts profits through longer equipment life, extended service intervals, reduction in energy use, fewer repairs and less inventory. LE’s arsenal includes highly trained consultants, technical expertise, a full complement of reliability products and services, and a comprehensive line of enhanced industrial and automotive lubricants.

The lubricants are formulated from highly refined or synthetic base oils and proprietary additives, ensuring that they exceed the performance of ordinary oils and greases. Lubrication Engineers operates under an ISO 9001 Certified Quality System.

Click here to read more about Lubrication Engineers and their products

Get in Touch

To talk to one of our team today and find out how we can help you with even your toughest lubrication challenges, please call us on 0800 612 3536 or email sales@purelubrication.co.uk